SITE MAP

서브 비주얼

Thank you for visiting ATS

ADVANCED TECHNOLOGY SOLUTION

컨텐츠

O-ring installation

O-ring Installation Tools

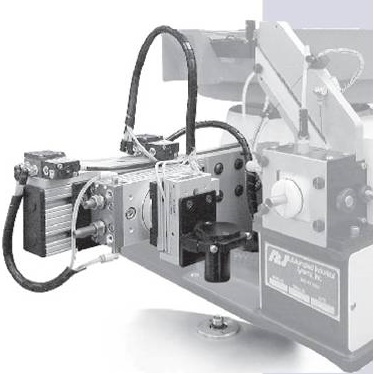

Internal O-ring/Snap Ring Installation Tool

- Product Features

- Now there’s an easy way to install O-Rings vertically onto components and

ssemblies. By using the Vertical Placement Module with the ASP-1 or ASP-2 O-Ring Installation Machine, an O-Ring can be quickly and accurately placed onto a part vertically.

- Product Information

1. Vertical Placement Module

Sequence Of Operation

• The ASP feeds and orients the O-Ring onto a staging mandrel.

• The transfer mandrel of the Vertical Placement Module then removes the O-Ring from the staging mandrel.

• Using a pneumatically controlled rotary actuator, the transfer mandrel rotates and precisely places the O-Ring onto the part in the desired position

Features

• Cycle Rates Up To 45 Times Per Minute (2,700 Per Hour)

• Rotational Angle of O-Ring Placement is Configurable

• Can Be Integrated Into Existing Production Lines

2. Vertical Placement Module

Sequence Of Operation

• Automated Industrial Systems has developed a hand held, manually loaded installation tool for placing o-rings and snap rings inside components and assemblies. The rings can be inserted into an internal groove or placed on a shoulder at the bottom of a bore.

•The HSP-1 (o-ring) and HRP-1 (snap ring) tools are ideal for use with larger components and hard to reach placement positions. They offer the advantage of being able to take the ring to the part

•The operator loads a ring into the magazine and places the barrel on the bore of the part where the ring will be installed. A trigger activates a small air cylinder that pushes the ring through tapered tooling in the barrel where it is compressed. The ring exits the barrel and snaps into place inside the bore.

Features

• Versatile and convenient.

• Pneumatically actuated.

• Low cost.

• Accommodates a variety of sizes and styles.

• Lightweight, 2.5 lbs.

• Can be used in any position.

• Improves quality.

• Increases production rate.

• Ergonomic design reduces operator fatigue.

• Accommodates rings up to 1.00” O.D.