에어 리크테스터

-

C-28WE Leak Tester

Versatile Test Capabilities

Pressure(Vacuum) Decay Leak rate

Pressure(Vacuum) Drop

Pressure Rate of Change

Occlusion(Back Pressure)

More information

The Sentinel C28 is a versatile and highly advanced multi-function leak test instrument that provides high-resolution pressure decay, vacuum decay, and occlusion leak testing with fast and repeatable results in a compact wall mount design.

Pressure Decay Test Types

• Pressure/Vacuum decay - leak standard

• Pressure/Vacuum decay - ΔP

• Pressure/Vacuum decay - ΔP/ΔT

• Occlusion - pressure or vacuum

HIGHLIGHTS

• High resolution pressure decay, vacuum decay, and occlusion leak testing

• -14.7 to 200 psig pressure ranges

• Program calibration with CTS Performance Factor Feedback for accuracy monitoring

• RS232, Telnet and Ethernet communication

• EtherNet/IP™ communication

• Auto program setup

• Global friendly control interface

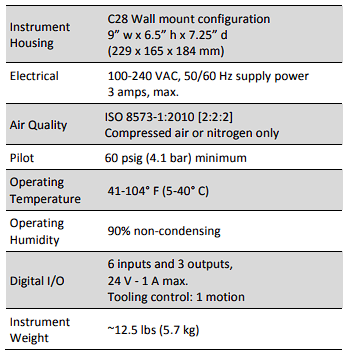

C28 SPECIFICATIONS

C28 Pressure Decay Feature

Pressure decay leak testing is the measurement of pressure loss over time. The use of absolute pressure transducers increases the accuracy of the test by measuring the pressure relative to a sealed vacuum reference, eliminating barometric pressure change issues.

Measurement Resolution

• Test Pressure / Pressure Loss

Displayed Resolution:

Range is selectable X - X.XXXXXX displayed units during pre-fill, fill, stabilize, test, and exhaust

Transducer Options:

Range Measurement Resolution

0-20 psia -14.7 to 5 psig 0.000004 psig

0-45 psia -14.7 to 30 psig 0.000008 psig

0-115 psia -14.7 to 100 psig 0.000021 psig

0-215 psia -14.7 to 200 psig 0.000040 psig

• Leak Rate

Displayed Resolution:

Range is selectable X - X.XXXXX displayed

Instrument Resolution: 0.0005 scc/min

Leak Standard

• Internal Leak Standard located on the valve manifold

Patented Auto Test Setup

• Automated optimization of test program based on maximum user allowable cycle time

• Simpifies instrument test programming and setup

Pressure Regulators

• Instrument maximum 1

• Manual regulator options

0.2 to 2.5 psiv (0.5-5 inHG)

0.5 to -12.7 psiv (1-26 inHG)

2.5 to -14.5 psiv (5-29 inHG)

0.2 to 2.0 psig

1.0 to 30.0 psig

2.0 to 100.0 psig

3.0 to 200.0 psig

• Electronic regulator options:

0.5 to 14.5 psiv (1-29.0 inHg)

0.5 to 2 psiv (0.1- 4 inHG)

0.02 to 0.5 psig (0.5-15 inH2O)

0.2 to 2.0 psig

1.0 to 30.0 psig

2.0 to 100.0 psig

3.0 to 200.0 psig

Quik Test Function

• Monitors the instantaneous in-test results and ends the testing process early when it is obvious that a reject or accept result is imminent

• Reduces test time

• Analyzes test results in real time

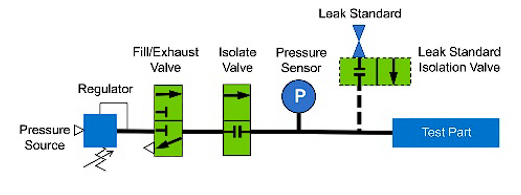

Pressure Decay Test Circuit

32 Test Programs

• Program selection and flexibility

• Pressure and vacuum test types

• Timers

• Pressure limits

• Reject limits

• Calibration parameters

• Units of measurement

• Digital I/O

• Seal control

Data Management & Storage:

• 30,000 tests stored in on-board memory

• Statistic data tracking for static trending capability

History length

Accept %

Reject %

Accept Average

Reject Average

Accept Std Deviation

Sample Size (since last reset)

• Resettable production counters:

Accept

Reject

Malfunction

• Test result log viewable on display

• USB for system backup, updates, and restore

Environmental Drift Correction

• Maintains calibration accuracy by monitoring and automatically making continuous small adjustments for changes in temperature and environmental conditions

Self-Test Functions:

• Internal leak detection process

• Program calibration verification (when a leak standard is used)

Automatic Calibration

• An easy to perform routine that calibrates the instrument to a “master part“

• Batch calibration to average over multiple parts, if required

• Permits manual edits of calibration data

Test Pressure Compensation

• Compares programmed test pressure to actual test pressure and correlates a comparative measurement for the

leak test to maintain accuracy

High-speed 32-bit Processor and 24-Bit A/D Converter

• Exceptionally fast, high resolution test processing

• Stable yet extremely responsive pressure/flow measurements

Units of Measure

• Pressure: ATM, Bar, cmHg, inHg, kPa, Mpa, mBar, mmHg, Pa, Torr, psia, psig, psiv, mmWC, iWC, cmWC, ksc

• Flow: sccm, sccs, scch, slpm, slps, slph, scfm, scfs, scfh

• Time: msec, sec, min

• All of the above selected globally or per test program

Test Ports

• 1 concurrent test port, standard

• 1/4” Colder fitting for test line connection

• Other connection sizes available (consult factory)

24 Volts Digital Inputs/Outputs

• 6 User configurable inputs

• 3 User configurable outputs

• Tooling control for one tooling motion and part presence

RS232 Communication Ports

• 2-Way communication

• Test result data transmission with definable fields

• Pressure streaming for waveform analysis

• Generated reports with test data and configuration

Ethernet Port

• 2-Way Telnet communication

• Email of reports, test data, and alerts

• EtherNet/IP™ Option, an additional 26 Inputs/25 Outputs

• Test result data transmission with definable fields

• Test Program Selection

Compact Enclosure Design

• Communication connections located at the side, test ports, and pressure regulators on the bottom of the unit

• Nema 12 industrial enclosure, die cast aluminum

Full-Color LCD Display

• 480 x 272 pixels

• User-friendly icon-based menus

• Menu operating modes: Basic , Advanced, Admin

• Displays active/inactive status of digital inputs & outputs

Selectable Menu Languages

• Language neutral operator interface

• English, Spanish, Chinese, Korean, and Portuguese language options

Test Result Lights

• For In-test, Accept, and Reject status results

• Eliminates stack lights

Password Security

• Select menu items to secure or unsecure

Help Menus

• On-screen popup window description of parameters

(activated by single shortcut key)

• Minimizes need to have the equipment manual present when programming the instrument

QualityWorX CTS DataHub™ Communications

The QualityWorX CTS DataHub is a turnkey solution that helps user collect, store, and analyze test results from CTS Sentinel Instruments

Each system includes:

• QualityWorX database and software solution for post test

data analysis

• Sciemetric Studio LT software for waveform and trend analysis

• External monitor

• Mouse and Keyboard