에어 리크테스터

-

A-28 Leak Tester

* Multi Language software

* RS232, Ethernet

* Color Graphic Display

Versatile Test Capabilities

*Differential Pressure Decay Leak Rate

*Differential Pressure (ΔP)

*Occlusion (Back Pressure)

Same pressure test pneumatics

performs various test methods

* Different part-to-part test parameters

* Test specific units of measurement

* Selectable digital input and output functions

* Utilizes RS232 and TCP/IP (Telnet)

communications methods to interface with the factory network.

More information

• Multi Language Software

• RS232, Ethernet

• Color Graphic Display

Versatile Test Capabilities

Differential Pressure Decay Leak Rate

Differential Pressure (∆P)

Occlusion (Back Pressure)

Instrument Flexibility accommodates:

- Same pressure test pneumatics performs various test methods

- Different part-to-part test parameters

- Test specific units of measurement

- Selectable digital input and output functions

- Utilizes RS232 and TCP/IP (Telnet) communications methods to interface with the factory network.

32 Part Programs with Application Flexibility

includes test type, timers, pressure, parameters, leak rates, calibration parameters, units of measurement, and digital input/output options.

Auto Calibration

routine tests master production part with internal calibrated leak standard to automatically establish the pressure-loss-over-time (or flow) to leak rate relationship for the part.

External Leak Standard Connection as a configuration option

Envirommental Drift Correction

maintains calibration accuracy by monitoring and automatically making continuous small adjustments for changes in temperature and environmental conditions.

Quik Test

monitors the instantaneous in-test results and ends the testing process early when it is obvious that a reject or accept result is imminent

Self Test Functions

include internal pneumatic leakcheck, calibration verification, transducer zero and span calibration, and test regulator adjustment.

Compact Modular Enclosure

for easy installation and maintenance (includes all electronics and pneumatics) in a wall mount configurations.

Wall Mount

6.5"h x 9"w x 7.25"d

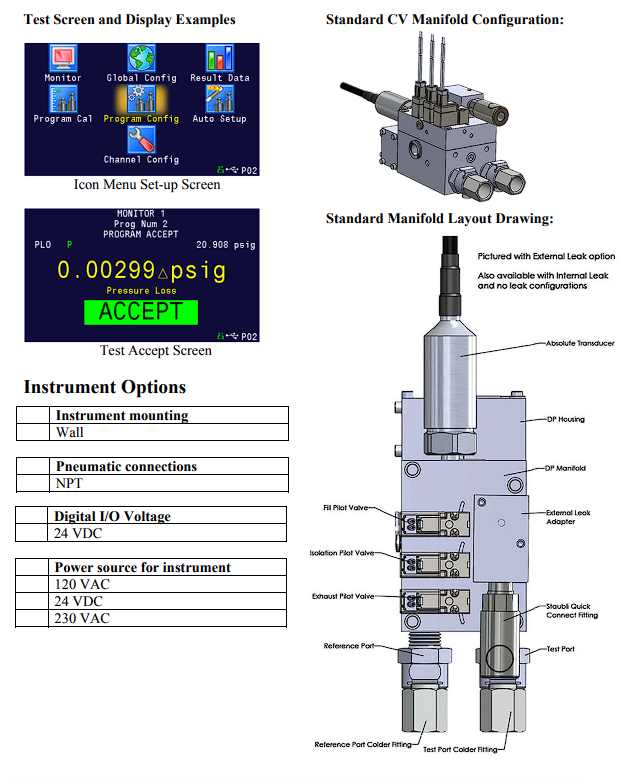

Modular Pneumatics

with manifold mounted valves, transducer, calibrated leak standard, and regulator.

Transducers

Absolute Pressure Transducer

Monitors test pressures for all tests and displays pressure relative to atmosphere (gage pressure).

Utilized during Pressure decay leak standard, ΔP/ΔT or ΔT, and Occlusion tests.

Differential Pressure Transducer

Utilized during the Differential Pressure Decay Leak Standard test. Measures the difference between the test part and a customer supplied reference volume. This is a calibrated rate of loss test to a certified leak standard

High resolution 24bit A/D

converter and patent pending signal conditioning for fast, repeatable test results.

High speed, powerful computer with 32 bit processor

for fast, high resolution processing

Monitoring and Programming

Viaintegral operator panel or remote computer. Remote part program selection using Binary digital inputs (1 to 6 digital inputs), RS232, or Ethernet.

Operator Display Panel

makes operator interface simple, fast and comprehensive

• Vivid, color LCD display with bar graph test results, digital test results, test parameters, counters, and test statistics. Icon menu screens for easy navigation.

• Test result lights for In test/Accept/Reject

• Language Neutral Keypad international icon design keypad accesses user friendly menu driven set up screens.

High Speed Communication via RS232 and Ethernet

includes test parameters, test results, counter information, and test statistics at baud rates up to 115200 for RS232. Test result output formats are selectable

Pressure Streaming

Test data output every 0.05 seconds via RS232 for plotting test curves.

Data Collection

Stores test results of leak/ flow rates, pressure loss, test pressure, time, date, and more for up to 5,000 tests.

Tooling Control

for simple applications includes an extend and retract output for part seal with one input start and part presence before start.

Easy setup performed within each part program.

Standard Integral 6Input/ 3Output Digital Interface

These inputs and outputs are independently programmable within each individual part program.

Programmable Digital Inputs

include Start, Stop/reset, Open Leak Std Valve, Part Presence, Ext. Switch feedback (before end of fill timer), Auto Cal, Hold, Vent/Halt, SPC Test Part, and 1-5 Binary Part Select.

Programmable Digital Outputs

include Test Accept/Reject per test, Part Accept/Reject, Outputs per test reject limits, Outputs for steps of test sequence, 1Tooling Extend, 1Tooling Retract, In Auto Cal sequences, and Press Select.

Specifications

Pneumatic Manifold

• Differential Pressure Decay Leak Rate, ∆P/∆T, ∆T, and Occlusion Tests

• Single Regulator* / Absolute Pressure Transducer/ Differential Pressure Transducer/ Single Leak Standard

• Standard Cv valves, Internal volume (less than 5 cc)

- Pressure ranges: vacuum - 200psig

- Test port: 1/4 in CPC LC100-04

- Supplied customer connection, CPC LC260-04

Instrument Resolution

• Test Pressure

- Displayed Pressure Resolution: Range is

selectable X - X.XXXXXX displayed units

during pre-fill, fill, and stabilize

- Gage Pressure Resolution: transducer range

(0.3 Pa for 200 psi range)

• Pressure Loss

- Displayed Pressure Resolution: Range is

selectable X - X.XXXXXX displayed units

during test and as a DP pressure loss.

- Differential Pressure Resolution of 0.007 Pa

transducer range.

• Leak

− Display X.XXXXX

− Resolvable to 0.00005 sccm

Electronic Regulator Option

• Limited range, consult factory for availability.

I/O Board Power Requirements

• Supplied independent of instrument power 24 VDC fused for 2.5 amp total

Control inputs are sinking

− 6 optically isolated inputs

Control outputs are sourcing

− 3 dry contact relays

Input/Output Terminals

• Integral 6 inputs and 3 outputs are available within the enclosure.

• Input and output functions per terminal are assigned within the part programs

Inputs include:

Start

Stop/reset

Part presence Halt/Vent

Hold Ext Press Sw

Program Cal Open Leak Std

Binary part select (B1-B5) SPC Test Part

Outputs include:

Part Accept Part Reject

Malfunction Severe Leak

ProgramCal Mode ProgramCal LS

ProgramCal Master Fill Valve

Press Select In Relax

In Pre-fill timer In fill timer

In stab timer In test timer

In Exh timer Below LL

Betw Lim Above HL

Test passed Test failed

Tool Mot 1extend Tool Mot 1

retract

Instrument Power Requirements

• 120 VAC-1amp

• 230 VAC-0.5amp

• 24 VDC - 2 amps

Part Program Storage

• Up to 32 part programs

Calibration System

- Optional NIST traceable calibrated leak standard sized to within +10%/-0% of specified reject rate with a measurement uncertainty of +/-1.4% of value. Mounted directly to pneumatic manifold.

- External Leak Connection available.

- Staubli RBE03 female connection

Communication:

- RS232 (on front of operator panel for external connection)

- 115600, 57800, 33600, 19200, or 9600 baud rate

- No parity, 8 bits, 1 stop bit, no flow control

Ethernet Port:

• 2-Way Telnet communication w/Email of reports, test data ,and alerts

• EtherNet/IP™ Option 26 Inputs/25 Outputs

• Test result data transmission with definable fields

• Test Program Selection

USB memory chip (Formatted FAT):

• Firmware update only

Enclosures:

− Nema 12 Industrial Enclosure

− Die cast aluminum

− Dimensions : 6.5” h x 9” w x 7.25” d

− Weight: 12.5 lbs (5.7 kg)

Ambient operating conditions

• 5deg to 40 deg C(41 to 104 deg F)

• Humidity: 90% non-condensing

Instrument Air Quality

• Required for both pilot and source, Class 2 air supply ISO 8573-1

• Air particles will be 1 μm or smaller

• Due point: <-40deg C

• Max. oil content: < 1mg/L or 1ppm