에어 리크테스터

-

LTC-502 Leak Tester

The LTC-502 leak tester is the startup model in our successful LTC leak tester series. The LTC-502 enables the complete functionality of the PC to be used for rapid and precise

measurements of pressure differences and flow, even in extreme situations. The integrated PC leaves nothing to be desired when it comes to user-friendliness. The future-oriented control using one button is intuitive and easy to operate.

Inputting errors are prevented. In addition, all parameters are easily manageable, so the subsequent assessment of the measuring processes can be carried out without difficulty.

More information

The LTC-502 leak tester is the startup model in our successful LTC leak tester series. The LTC-502 enables the complete functionality of the PC to be used for rapid and precise measurements of pressure differences and flow, even in extreme situations. The integrated PC leaves nothing to be desired when it comes to user-friendliness. The future-oriented control using one button is intuitive and easy to operate. Inputting errors are prevented. In addition, all parameters are easily manageable, so the subsequent assessment of the measuring processes can be carried out without difficulty. The LTC-502 communicates directly with all the peripherals for transfer, management and analysis of data and machine control. The test process becomes noticeably more efficient. Another technological innovation is the unique analog module with the 24-bit A/D converter. The module enables an unequalled detailed discrimination of the measuring signal. This means that a huge amount of extra information is available for monitoring the measuring process and ensuring that the measurements can be reproduced as accurately as possible. Considering the outstanding measuring concept and the wide range of different functions, the LTC-502 is on sale at a particularly attractive price. This makes it an investment with an assured future on all fronts.

LTC-502 – the innovation for standard solutions

The LTC-502 puts into practice the know-how and

experience of more than 30 years in leak test technology. It can be used for the most diverse test specifications, such as:

• Test pressures – from vacuum to 20 bar over-

pressure

• Test times – in milliseconds, seconds and minutes

• Leak rates – for all kinds of functional leakage tests

• Pressure differences – from 0.1 Pa to 5000 Pa

• Test volume – from a few millilitres to 10 litres

• Environmental conditions – with special adaptations for a wide range of sectors (temperature, etc.)

The LTC-502 offers virtually unlimited possibilities for all kinds of leak measurement tests using the differential pressure and flow methods.

Good contactual characteristics and connection guarantee

The PC platform and the software developed for the LTC-502 enable the connection of peripherals such as:

• Printer with USB interface

• Printer with parallel interface

• Marker units

• Machine control

• Modem analog and ISDN

• USB stick

• Programmable control for in- and outputs to control a tool

The communication marvel that speaks your language

The LTC-502 has an effective language module with up to 15 different languages such as German, English, Spanish and many others. Language selections are made easy via the menu. All measurement data can be stored on the PC or on an USB stick for later analysis or archiving. Software extensions or hardware configurations can be installed – automatically – via the USB stick. Updates can be loaded on the USB stick, by e-mail or via Internet. The LTC-502 can be extended to include all world languages at any time, anywhere, by e-mail and USB stick.

Service is our strength – we are ready to start

Our technicians are available to offer on-site advice and support right beside your machines and work stations.

We will assess your individual test situation and configure the LTC-502 on the basis of the required task setting.

As a service we offer test measurements and initial samplings in our laboratory.

In addition, depending on your contract, we will make our 24 hour service available to you.

Our service also includes:

• Method advice and optimisation of measurement data

• Calibration service and maintenance

• Technical support, even for the products of third parties

• Measuring system analyses

• LTC-502 hire equipment, available immediately

• Hire equipment for leak-rate simulation

Assess it on its performance

PC platform

• Full PDC functionality

• A USB modem or printer can be connected(Plug & play)

• can be connected and operated using remote control

USB stick

• Data security

• Data back-up

• Data storage

• Parameter control via Excel(data transfer between PC and LTC-502)

• Parameter transfer between different LTC

• Installation of updates such as language modules, Network configuration, printer drivers with automatic installation

Device versions

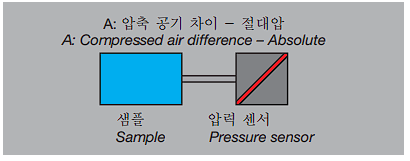

• Absolute pressure difference

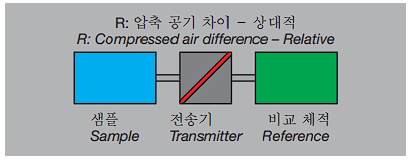

• Relative pressure difference

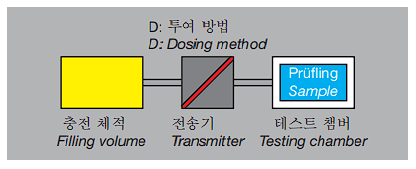

• Dose method

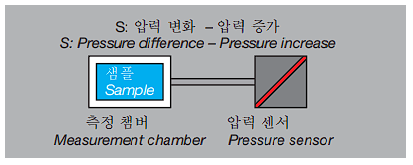

• Pressure increase

• Volume and flow rate measurement

Special solutions

• Combination of various tests

• Hydrodynamic pressure or opening tests

• Testing battery,"High-speed"model

• Testing battery with extra large flow

Service

• Service monitoring with cycle and operating hour counter

• Replacement equipment for use during service or maintenance work

• Display of switch status of inputs and outputs on integration in an automatic test system

Monitoring equipment

Corresponding monitoring equipment is available for the LTC-502 leak tester:

• Adjustable calibration leakage

• Fixed calibration leakage

Product Features

• Test pressures : from vacuum to 20 bar over-pressure

• Test times: in milliseconds, seconds and minutes

• Leak rates : for all kinds of functional leakage tests

• Pressure differences : 0.1Pa ~ 5000Pa

• Test volume : from a few millilitres to 10litres

• Environmental conditions : with special adapta-tions for a wide range of sectors(temperature, etc.)

• Data storage : 2000ea(optional : 2,000,000 measurements)

• 24-bit analog - digital converter

• Languages : German, English, French, Spanish

• Interfaces : 8digital inputs/outputs for external controller, 2USB port

Product specifications

• Device data : System pressure 1.0bar above test pressure, mains connection 230V, 50Hz, 40 VA slow-blow fueses

•Device Size : 305 * 170 * 300mm(B*H*D) / 8kg

General Information

We have developed the leak tester of the LTC-502 series especially for the economical and accurate testing of casted, blown, welded, glued, closed and screwed parts, assembly groups and complete devices. You are provided with these in six different measuring procedures. Our many years of experience in leakage testing tasks, perfected pneumatic systems and state-of-the-art PC technologies offer substantial advantages in practice.

Test medium

Compressed air, nitrogen and non-aggressive gasses, oil and dust-free, special versions for water and forming gas, others upon request

Parameter storage and backup 100 free selectable testing programs, 2 years of data storage without mains power, access via password

to-user administration, user interface and set-up interface, storage of last 2,000 measured results, can be optionally enhanced, automatic storage of all process data on a USB stick

Operation

Single-knob operation, external operation, Menu-driven with on-screen help function

Display

Data and measured value display, data memory with last 2,000 measured results, statistics, summator, maintenance counter, operating hours counter, display of inputs / outputs for external control, good / bad messages on display and LEDs

Languages

Can be switched between: German, English, French, Spanish; other languages upon request

Interfaces

Parallel: printer outputs etc., serial: modem, PC data transmission, external test parameter administration, 8 digital inputs / outputs for external controller, 2 USB ports, 1 hard disk connection (EIDE), program selector for external control

Device versions

Absolute pressure difference, relative pressure difference, dose method, pressure increase, volume and flow rate measurement

Device data

System pressure 1.0 bar above test pressure, mains connection 230 V, 50 Hz, 40 VA slow-blow fuses, dimensions 350 x 170 x 300 mm (B x H x D), ½ 19“, 3 HE, weight approx. 8 kg

Device accessories

Mains cable 2.5 m, ext. power supply, test air line 3 m, various screwed connections, operating manual, factory certification, Fine filter with water separator for the test air inlet, DKD certificate also available against payment upon request

Optional accessories

Lockable front door, remote control, test leak, printer, modem, automatic parameter evaluation, automatic volume evaluation, memory enhancement for measurement results up to 1 million, temperature compensation, functional inspection (opening point), closed components (closed sample)

The following generally applies for all measurement procedures

Menu with windows technology

4-line, delighted display with 4 x 40 characters

Interface for PLC, printer

Measurement data administration, shift administration

Expandable with hard disc and monitor

USB interface

Extremely short testing times

Electrical inputs and outputs for the device controller

Parameter sets for 100 programs

Configurable individual masks

Language selection

Statistic function

Program procedure control freely configurable

Software update via USB stick

Data storage and transfer via USB stick

Copy function

Parameter change history

Remote maintenance capable

Tracability of parameter changes

Absolute pressure differential measurement

Application

ABS components, intake manifolds, exhaust systems, brake cylinder, different parts for engines, flow heaters, injection nozzles, bellows,

window lifting motors, gas fittings, gas meters, drives, rear axles, catalytic converters, air conditioners, carburettors, oil sumps, compensators,

coupling lines, lamps, engine blocks, pumps and many more.

Test pressures

Depending on the application and device types, stageless programming

from -0.1 to -1.0 bar; -1.0 to +1.0 bar; 0.05 to 1.0 bar; 0.1 to 5.0 bar; 0.2 to

10.0 bar; 0.5 to 20.0 bar; further pressure ranges upon request

Measuring ensor

Temperature-compensated measuring sensor, pressure-measuring range

according to device configuration, pressure resolution 0.1 or 1 Pa

Other measuring ranges upon request

Testing parameters

All times 0.1 ... 999 sec, test pressures, shock filling, limit in Pa and ml/min,

series errors, automatic test leakage connection, shift administration,

measured value in Pa, mm water column, mbar, ml/min

Relative pressure differential measurement

Application

ABS components, intake manifolds, exhaust systems, brake cylinder, different parts for engines, flow heaters, injection nozzles, bellows, window lifting motors, gas fittings, gas meters, drives, rear axles, catalytic converters, vaporiser, air conditioners, carburettors, oil sumps, compensators, coupling lines, lamps, engine blocks, pumps and many more.

Test pressure

Depending on the application and device types, stageless programming from -0.1 to -1 bar; -1.0 to +1.0 bar; 0.05 to 1.0 bar; 0.05 to 5.0 bar; 0.2 to

10.0 bar; 0.5 to 20.0 bar; further pressure ranges upon request

Measuring ensor

Temperature-compensated measuring sensor, pressure-measuring range according to device configuration, pressure resolution 0.1 or 1 Pa

Other measuring ranges upon request

Testing parameters

All times 0.1 ... 999 sec, test pressures, shock filling, limit in Pa and ml/min, series errors, automatic test leakage connection, shift administration,

measured value in Pa, mm water column, mbar, ml/min.

Pressure differential measurement dosing method Ein

Application

ABS components, intake manifolds, exhaust systems, brake cylinder, different parts for engines, flow heaters, injection nozzles, bellows, window lifting motors, gas fittings, gas meters, drives, rear axles, catalytic converters, air conditioners, carburettors, oil sumps, compensators, coupling lines, lamps, engine blocks, pumps and many more.

Test pressure

Depending on the application and device types, stageless programming from -0.1 to -1.0 bar; -1.0 to +1.0 bar; 0.05 to 1.0 bar; 0.05 to 5.0 bar; 0.2 to 10.0 bar; 0.5 to 20.0 bar; further pressure ranges upon request

Measuring ensor

Temperature-compensated measuring sensor, pressure-measuring range

according to device configuration, pressure resolution 0.1 or 1 Pa

Other measuring ranges upon request

Testing parameters

All times 0.1 ... 999 sec, test pressures, limit in Pa and ml/min, series errors, automatic test leakage connection, shift administration, measured value in

Pa, mm water column, mbar, ml/min.

Pressure increase measurement

Application

ABS components, airbag components, aerial motors, pressure vessels, electric toothbrushes, infusion bags, corpus, relays, oxygen / compressed air connections, suction jet pumps, sliding / tilting sunroof motors, packaging, sealing caps, water fittings, kettles, water metres, cylinder head hoods and many more.

Test pressures

Depending on the application and device types, stageless programming from -0.1 to -1.0 bar; -1.0 to +1.0 bar; 0.05 to 1.0 bar; 0.1 to 5.0 bar; 0.2 to

10.0 bar; 0.5 to 20.0 bar; further pressure ranges upon request

Measuring sensor

Temperature-compensated measuring sensor, pressure-measuring range according to device configuration, pressure resolution 0.1 or 1 Pa

Other measuring ranges upon request

Testing parameters

All times 0.1 ... 999 sec, test pressures, limit in Pa and ml/min, series errors, automatic test leakage connection, shift administration, measured value in

Pa, mm water column, mbar, ml/min.

A flow meter of the state-of-the-art generation

Application

ABS components, fittings, baffles, burners, dialysis filter, gas components, drive housing, hydraulic components, catheter, condenser, fuel lines, silencer, distributor blocks, valves, heat exchangers and many more.

Test pressure

Depending on the application and device types, stageless programming from -0.1 to -1.0 bar; -1.0 to +1.0 bar; 0.05 to 1.0 bar; 0.1 to 5.0 bar; 0.2 to

10.0 bar; 0.5 to 20.0 bar; further pressure ranges upon request

Measuring cell

Flow range 0-50 ml/min, Flow resolution 0.1 ml/min

Other measuring ranges upon request

Testing parameters

All times 0.1 ... 999 sec, test pressures, limit in Pa and ml/min, series errors, automatic test leakage connection, shift administration, measured value in Pa, mm water column, mbar, ml/min, ml/min, ml/h, l/h and mbarl/s

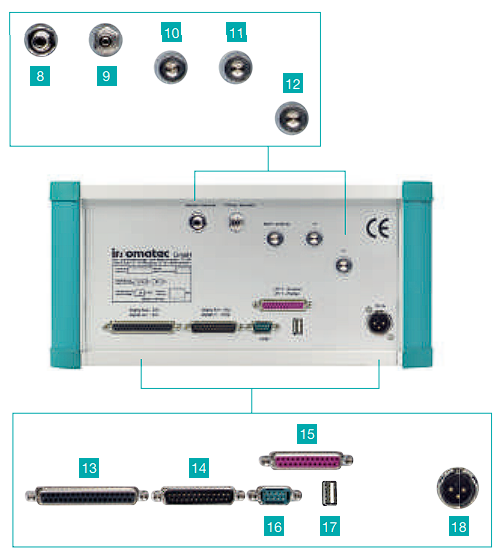

Display, operating elements, connections and interfaces

1. LCD display with 4 x 40 characters

Display setpoint and actual values, measurement value can be switched to Pa, mm water column, mbar, ml/min and cm3/min

2. Single button operation (menu-driven)

3. Good / bad displays (1st and 2nd measuring circuits)

4. Mains switch (On/Off)

5. Start/Stop buttons

6. USB port in the front (one of 2)

7. Connection for the test leak coupling

8. Main air connection

9. Test air connection

10. Extraction air

11. Multi-port connection, e. g. reference; 2. Specimen connection

12. Control air connection (optional)

13. Digital input

14. Digital output

15. Printer connection

16. RS232 | RS232

17. 1 USB-Port / 1 USB port

18. DC power supply

Optional accessories

Measurement and Quick Connector Systems

The DIGIFLOW 2003 is a variable leak calibrator which is used to professionally test leak measuring devices and/or entire leak test systems for quality assurance. The DIGIFLOW 2003 will be connected in parallel with a dense sample which leak rate will be checked and adjusted on the DIGIFLOW 2003.

The leak measuring device or the leak test system has to recognise the leak simulated by the DIGIFLOW 2003. In this way, the efficiency of the entire test system can be easily, quickly, and cost-effectively controlled – at every opportunity, shift changeover, tool change, or special incidents.

The innomatec test leak can be used for all test methods (pressure difference, flow, tracer gas). Appropriate accessories and adaptions for the connection to your equipment are available. It can also be directly integrated into a test piece.