Dot-peen & Scribe Marker

-

C-Series, Dot-Peen & Scribe Custom Solutions

Versatile marking system offering both Dot-Peen and “Silent Scribe” marking in the same system. This ball screw drive system comes with either stepper drives offering up to 5 characters per second, or high speed servo drives offering up to 8 characters per second.

The system controller offers the flexibility of DC start and mark complete signals, as well as serial and digital I/O communication. This system is UID/2D Square-Dot® Compatible. -

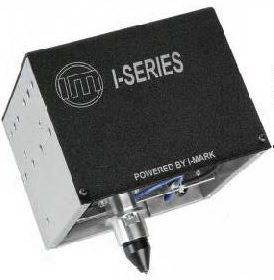

I-Series Dot-Peen Unit

Compact industrial integration dot-peen marking system with heavy duty frame and linear rail guidance system to ensure precise operation. The marking speed is 3-5 characters per second.

It has a very small foot print with 3 sides available for mounting. These systems come with two marking window options: medium and large size. The I-Mark controller uses the latest in drive technology. -

I-Series Silent Scribe

"Silent Scribe" version of the popular I-Series Dot-Peen. This ball screw drive system has a marking speed of 4 characters per second in scribe mode. The systems come with two marking window options: medium and large size. This system is UID/2D Square-Dot® Compatible. The I-Mark controller uses the latest in drive technology. -

M-Series Marking Machines

The complete I-Mark bench-top dot-peen marking system is offered in two versions:

1) Standard for marking flats,

2) With a third axis for

marking the OD of round parts.

M-Series dot-peen systems

mark a wide variety of metal and plastic parts with a selection of fonts for

lpha/numeric, serial numbers, date codes, logos, and 2D codes. This machine features the easy to use I-Mark software. Options include: a selection of marking windows and an operator touch screen upgrade. These systems are good solutions for moderate production (250-750 parts per shift) marking requirements. -

Model 100 I-Mark Controller

Basic marking machine controller includes I-Mark controller, monitor, keyboard with integrated mouse, and cables. This system will control all CMT programmable systems with two or three axes, and has an integrated motherboard with preloaded I-Mark programming software. This controller is designed for Basic Marking Station Functionality, and has limited I/O. -

Model 200 I-Mark Controller

The I-Mark controller is designed for easy integration. It features compact size and a selection of communications functions including: Serial, I/O, Modbus, and Ethernet IP. The standard controller is programmed with a customer provided PC using the I-Mark software. Using this same software the system may be monitored via a LAN. Upgrade options include an integrated PC, standard or touch screen monitor, and keyboard. -

Model 300 I-Mark Controller: Dual Marking Heads

Expanded controller offers options including motion, axes or dual machine controls. All the functionality of the I-Mark controller including the selection of communications options and the advanced networking capabilities. -

Handy Andy

This complete bench top dot-peen marking system is the most economical marker in its class. It is now available with a third axis as an option for marking the OD of round

parts, and is great for low volume applications where flexibility is required (<250 parts per day). -

Options

Available options include part touch-off auto-start, stands, pedestals, machine bases, vises and custom part fixtures. CMT offers custom marking solutions to include part handling and vision systems. Each of these systems is custom designed to meet application requirements.