내경 오링삽입기

-

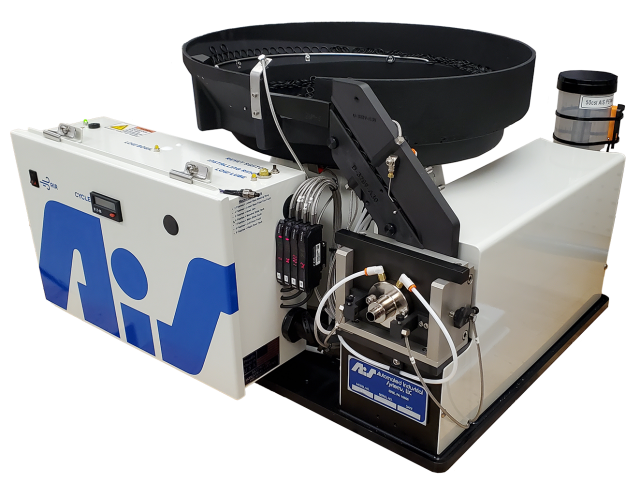

Internal O-ring Installation M/C(ISP-2)

Now there is a fast, easy and accurate way to install O-rings into parts and

assemblies. The ISP-2 Installation Machine can position O-rings and seals up to

2.25” O.D. into a desired part. The O-rings or seals are fed by a vibratory feeder bowl into a track where they are positioned onto an installation mandrel. The operator then lightly pushes the part into the mandrel and the O-ring or seal is automatically installed at the specified location.

More information

Now there is a fast, easy and accurate way to install O-rings into parts and assemblies. The ISP-2 Installation Machine can position O-rings and seals up to 2.25” O.D. into a desired part. The O-rings or seals are fed by a vibratory feeder bowl into a track where they are positioned onto an installation mandrel. The operator then lightly pushes the part into the mandrel and the O-ring or seal is automatically installed at the specified location.

Features

• Benchtop Machine

• Installation Rate up to 30 Cycles/ Minute (1,800 per hour)

• Digital Counter

• Right-hand or Left-hand Configuration

• Easy Tooling Change-Over (Less than 10 minutes)

• PLC can Easily be Expanded for Automated System

• Installs

- O-Rings - Quad Rings - Teflon® Seals - Crimp Seal

Standard ISP-2 Dimensions

• Width 26.88” ( 682.75 mm) x Depth 28.56” (725.42 mm) x Height 18.50” (469.90 mm)

* Foot pedal required for machines not incorporated into automated system.

Machine Specifications

• 115 VAC, 60 Hz. (Other voltages available on request.)

• 90 psi (6.205 bar) air supply.

Ring or Seal Specifications

• 1.01”- 2.25” O.D. (25.65 mm - 57.15 mm)

*Application Limitations will vary depending on O-ring or seal O.D.,cross section and material composition.

NOTE: For applications with O-rings or seals 1” or smaller,see our ISP-1 machine

ISP-2 Oprions

• Low Lube Reservoir Sensor - Shuts down the machine when lubricant reservoir needs refilling.

• Work Stand - Steel constructed stand provides sturdy base for machine operation.

• Stainless Steel Parts - Available for “clean room” applications